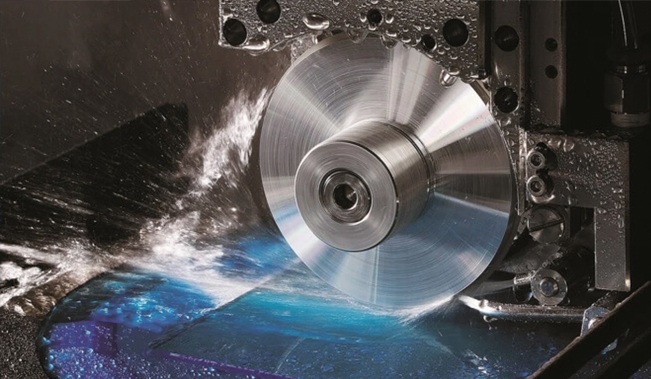

Wafer Dicing

Services

Request advanced blade dicing, laser dicing, and low-k grooving services from industry leader Disco Hi-Tec America.

Contact Sales

DICING

Request Forms

Fill out the appropriate form below to request wafer dicing services from DISCO HI-TEC America.

DISCO Test Cut Request Form

DISCO Test Grind Request Form

DISCO Test Laser Cut Request Form

Wafer fabs continually face challenges in manufacturing semiconductor devices because the devices continue to get tinier and more complicated. Integrated circuits continue to increase in circuit density. Trends in chip design and materials, such as using die attach films and wafers as thin as 50 μm, add to the complexity of manufacturing.

Disco can offer you services with an experienced team and world-renowned tools, from our facility in Santa Clara, California.

We welcome small batch quantities for R&D purposes to large batch quantities for production. Inquire today by completing the test cut request.

Introducing various processing technologies to further improve quality and productivity with the current blade dicing, such as thin silicon dicing and measures to prevent contamination of the processing surface.

In recent years, with the increased adoption of IC cards, RFID tags, and SIP (system in package) for cellular phones and other mobile products, the market for finished semiconductor die 100 µm thick or less has grown rapidly. This high demand has in turn made the processing of thin wafers an essential competence for many device manufacturers. To provide the processing results that these companies require, DISCO continuously researches and develops the machines, blades, and applications that make thin wafer dicing a reality.

Learn More About DISCO Thin Wafer Dicing

In the past, the processing of QFN (Quad Flat No-Lead) packages was performed with routers and other machine tools, but now that smaller and more varied packages are common, the use of a dicing saw has become more and more popular. DISCO’s dicing saws can offer higher singulation throughput and productivity as well as less copper burring, while DISCO’s new resinoid blade for package singulation can significantly improve process quality.

Learn more about DISCO QFN Package Processing

Introducing various grinding wheels and handling mechanisms to support the increase in demand for less than 100 µm thin grinding, and newly developed wafer grinding technologies. This includes ultra-thin grinding capabilities

In recent years, the demand for ultra-thin die for use in mobile phones, stacked packages, and a myriad of other applications has been increasing. DISCO delivers complete ultra-thin grinding solutions that comprise four key elements: machine, grinding wheel, protective tape, and processing conditions.

Learn More About DISCO Ultra-Thin Grinding

Laser dicing is a technology that DISCO has focused on in recent years as a pillar of technology, alongside blade dicing. Introducing processing technologies that utilize the special characteristics of lasers, such as improved processing speed and cutting of compound material.

“Stealth Dicing treatment” forms a modified layer in the workpiece by focusing a laser inside the workpiece, and then a tape expander is used to separate the die. Stealth dicing is expected to increase the number of die that can be obtained from a wafer compared to normal dicing because it is possible to make the necessary street width (cut width) narrower. This is a particularly effective processing method for long shaped die, such as line sensors.

Learn More About DISCO Stealth Dicing Treatment

Compound semiconductors, such as GaAs (Gallium Arsenide), are used in high frequency devices. When blade dicing compound semiconductors with an existing diamond blade, the feed speed is slow and high productivity is difficult to obtain. With the trend towards high integration, based on such technology as SiP (System in Package), high-strength thin-die manufacturing technology has become necessary. However, with blade dicing, as the thickness of the wafer becomes thinner, dicing difficulty increases.

To solve this kind of issue, DISCO has optimized the laser head and optical system of the DFL7160 laser saw to establish a laser full cut application

Learn More About DISCO Laser Full Cut Dicing

Makers employing Low-k material and copper in high-speed devices experience significant bottlenecks, as this material is difficult to blade-dice at standard speeds. Further, acceptable cut quality is hard to obtain. DISCO’s engineers have developed an application that solves these issues.

Learn More About DISCO Low-K Grooving

Contact Us Today For More Information

Get more information about our full line of solutions, including test & inspection equipment.